EWEB Lab & back-up services building

As part of a larger water and chemical testing facility built in the 1970s, MWA designed an additional concrete laboratory to meet the evolving needs of EWEB’s staff. Located in the hills of Springfield, the facility needed updates to its design and structure to accommodate the various services provided by the company. With a strategic layout and new technological features, the renovated building offers staff an elevated workspace that combines functionality and contemporary design.

PROJECT CONTACT

LOCATION

Springfield, OR

OWNER

Eugene Water & Electric Board

CONTRACTOR

Pacific Excavation Inc.

SIZE

3,874 SF

COMPLETED

2020

PHOTOGRAPHER

David Papazian

Expanding the pre-existing facilities, MWA needed to maintain a similar aesthetic, while updating the laboratory’s structural and functional capabilities. The concrete exterior created a minimalistic and seismically sound structure that will last over 100 years. In keeping with the simple exterior, black details in the awning and typography were added to the building’s façade to match elements on the other buildings. Contrasting the brutalist style of the building, regional landscaping and a picnic table provide staff with a serene environment during their breaks.

Situated in the hills of Springfield, the foundation of the building was built into the basalt rock, ensuring a sturdy and long-lasting structure.

Large monitors in the conference room and additional space for high powered office equipment allow staff to conduct business and communication operations in one building.

Considering the complexities of testing facilities, MWA designed a building that allows EWEB staff to travel seamlessly through the lab with integrated technology enhancing their workflow. The designers worked closely with employees to configure the layout, creating efficient circulation between workspaces, and adding designated rooms for business administration offices and a microbiology lab. With EWEB’s growing communication needs, a conference room was added for meetings, along with a highly controlled A/C computer area for employees to conduct business. A vestibule off the entrance separates the administrative sector from the laboratory to protect the integrity of the testing process. Understanding the intricacies of lab work, the designers created an intuitive layout.

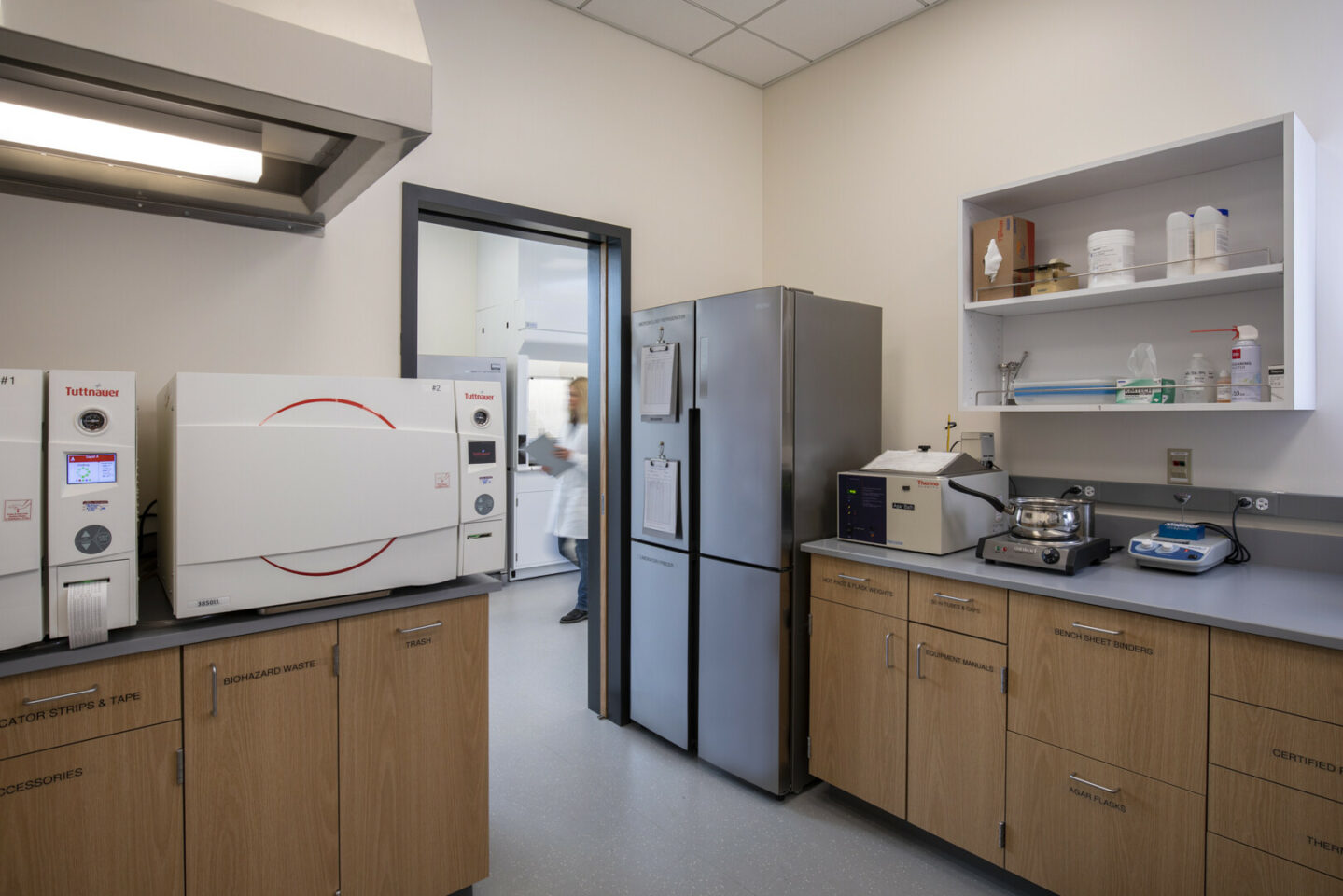

Stainless steel appliances, such as a large fridge for storing organic testing materials, were added to increase lab capabilities.

With many high-contact surfaces and lab-specific requirements, the interiors needed to be durable and highly functional. Following MWA’s standards for successful lab design, materials were chosen to improve the longevity of the lab. Epoxy counters provide an almost indestructible surface for the lab technicians to conduct water and mineral tests. Rubber floors were installed as an easy to clean and more comfortable surface to stand on. To ensure safe and efficient processes, the designers added elements such as doorless cabinets with protective bars to keep supplies in place, as well as an integrated emergency shower in the lab. Strategically chosen materials and amenities improved the accessibility and functionality of the building.

Canopy hoods were installed over testing areas to mitigate air quality and potential fumes.